Explore the Next Generation of

Sterilization Technology

The Future of Sterilization Workshop at MD&M West explores the technologies and trends transforming how medical devices are sterilized for safety, performance, and sustainability. This one-day course delivers a deep dive into next-generation modalities—including Supercritical Carbon Dioxide, Vaporized Hydrogen Peroxide, Chlorine Dioxide, Nitrogen Dioxide, Electron Beam, and X-Ray sterilization.

You’ll gain practical insights into validation, scalability, material compatibility, and regulatory expectations to help your organization transition from legacy methods to more sustainable, efficient solutions.

Why Attend?

Advance Your Knowledge of Technologies Shaping Sterilization’s Future

Workshop Topics

Testing & Implementation

Learn how to evaluate feasibility, test protocols, and scale from R&D through commercialization when adopting new sterilization methods.

Efficacy & Material Compatibility

Assess how alternative modalities ensure broad-spectrum microbial kill rates while maintaining material and packaging integrity.

Temperature Sensitivity & Penetration

Understand how low-temperature and high-penetration methods ensure safety for complex, heat-sensitive devices.

Sustainability & Cost-Effectiveness

Explore how new methods reduce emissions, waste, and resource consumption while lowering long-term operational costs.

Regulatory Approval & Scalability

Navigate evolving global standards for sterilization validation and learn how to prepare for audits and large-scale implementation.

Who Should Attend

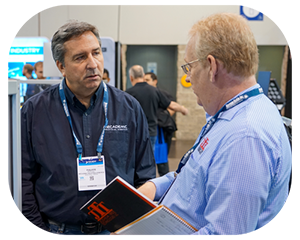

Who You’ll Meet

Join Our Community of Innovators

The Sustainable Manufacturing Conference brings together a diverse community of professionals committed to advancing sustainable practices:

Choose The Pass Bundle That Works Best For You

Enhance your expertise with a full day of hands-on sterilization training or bundle it with the three-day MedTech Conference for the complete experience. Deepen your understanding of how sterilization technologies intersect with medical device design, manufacturing, and regulatory innovation for safer, more efficient, and sustainable product lifecycles.

All passes include full access to the MD&M West expo and free on-floor education.